A Commitment to Sustainability

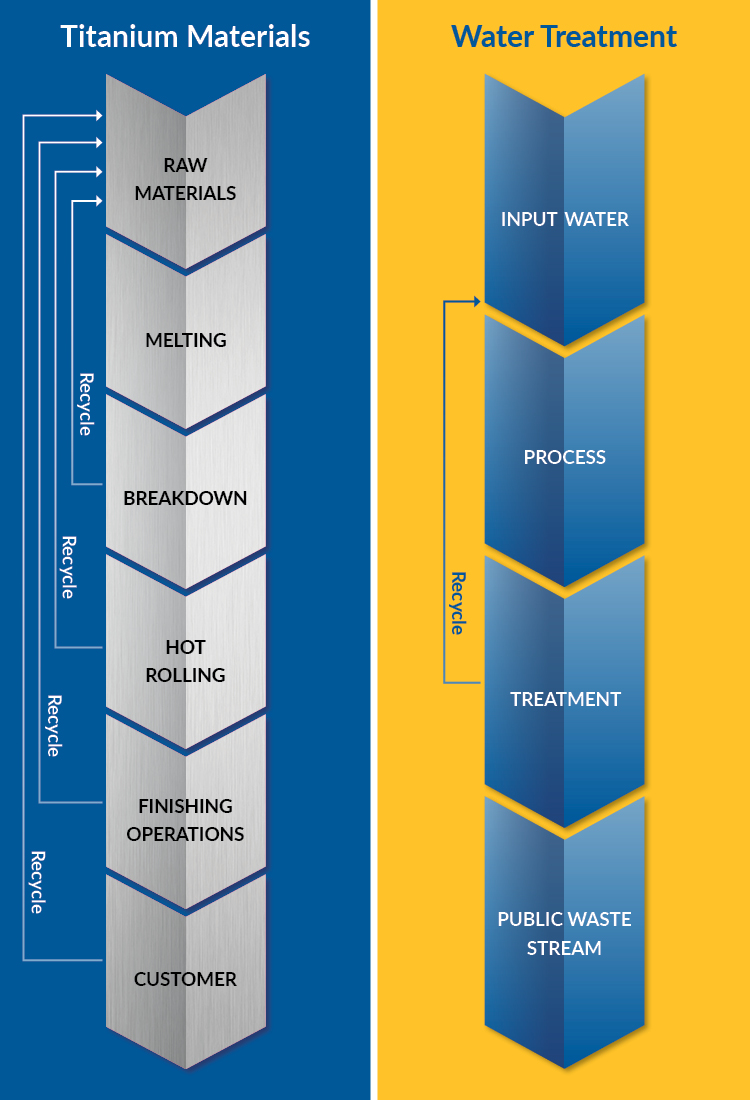

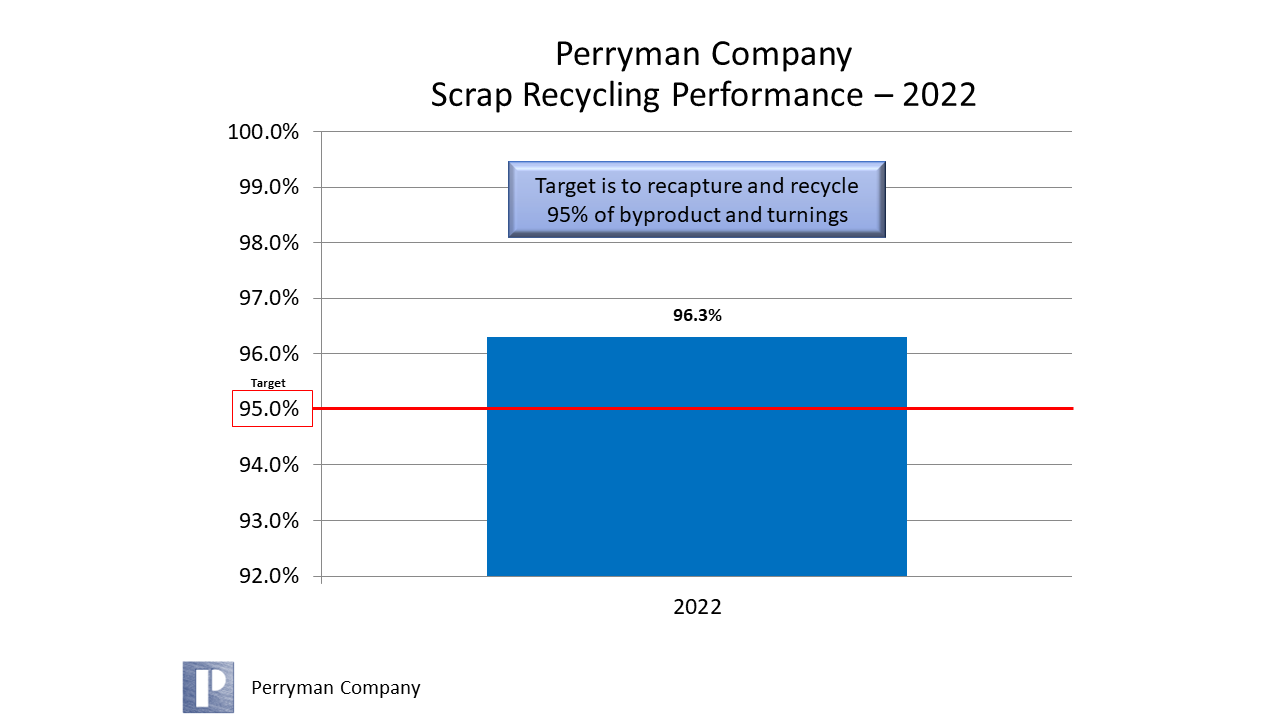

Perryman understands the importance of mitigating our impact on the environment and improving operational efficiency. That’s why we capture and recycle nearly 95% of the byproduct and turnings from our internally processed semi-finished and finished titanium materials.

We also actively collect clean titanium from participating customers, and purchase recycled titanium from approved providers as an additional source of raw material feedstock. These materials are reintroduced into our melting practice as a part of our fully integrated process.

Less waste and greater utilization of recycled materials increases our efficiency, decreases product costs, and reduces our impact on the environment.

Water Treatment

The water used in our recycling process is collected, treated, and reintroduced into our operational facilities. Internally recycling waste water ensures that public water is not contaminated.

Vacuum Melting Processes

Our titanium is double melted through Electron Cold Hearth Melting (ECHB) and Vacuum Arc Remelt (VAR) technologies, which optimizes management of raw materials. Because they are under vacuum, Perryman’s melting process releases zero emissions or contaminates.

Induction Heating

We prepare titanium material for processing through induction heating, which produces zero carbon emissions. Unlike traditional gas furnaces methods, which typically run constantly and produces a carbon footprint, our technique only uses power for induction heating as needed, which means no wasted energy or natural resources.

Paperless Culture

Perryman has embraced an ongoing paperless initiative that utilizes state-of-the-art computer software for bar coding, material testing and tracking, and internal electronic file sharing. Not only do these systems reduce paper waste, they also provide tremendous efficiencies in communication, accuracy, and decision-making.

Used Paper and Metals Recycling

Perryman collects materials that we are unable to recycle internally, such as paper, cardboard, and metals used in office environments and manufacturing facilities, and sends them to recycling companies.

We have established specific sustainability targets which may be reviewed during authorized onsite audits and customer visits or based on requests.

Environmental, Health & Safety Policy Statement

Perryman will uphold the following guiding principles in all of our business activities through management commitment, employee involvement and allocation of adequate personnel and other resources.

Compliance: Manage our business activities to comply with all governmental laws and regulations as well as internally established environmental, health, and safety requirements.

Protection: Conduct activities in a responsible manner to protect employees, the public, and the environment by focusing on injury and illness prevention, pollution prevention and minimizing impacts and risks to the environment from our operations.

Improvement: Maintain and continually improve our environmental, health, and safety management systems.

Progress Tracking

In 2022, we exceeded our scrap recycling goal. We will strive to do even better in 2023.

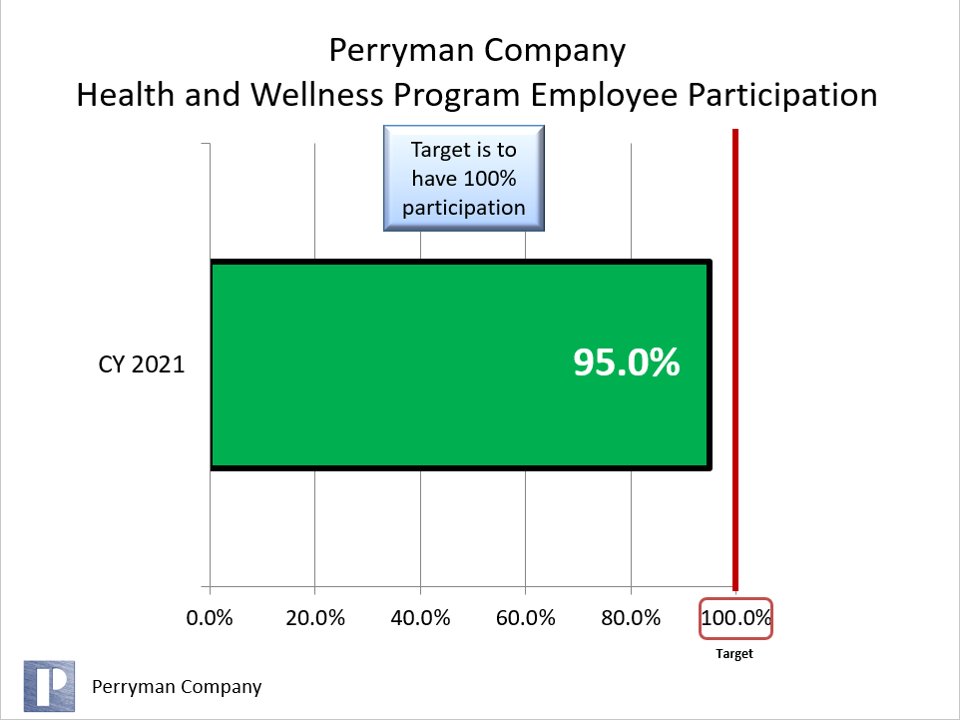

In addition to our commitment to the environment, Perryman emphasizes a commitment to the health of our employees. Last year, 95% of our employees participated in our employee health and wellness program. Our goal each year is to achieve 100% participation.